Our Capabilities:

- Pump, Motor, Valve & PTO Refurbishment

- Winch & Gearbox Repair

- Hydraulic Cylinder Repair

- Hydraulic Cylinder Manufacturing

- Mobile Equipment Service

- Remanufacture & Retrofit Existing Equipment

- Hydraulic Power Units & Controls

- Custom Machining & Fabrication

- Industrial Hard Chrome Plating

- Mobile Service

- Preventative Maintenance Contracts

- Service Exchange Program

Hydraulic Cylinder Repair:

Cylinder repair can be a cost effective alternative to outright replacement.

We offer our clients a full range of cylinder services, from dismantling and diagnosis, to complete reconditioning services.

Cylinder repair can be a cost effective alternative to outright replacement.

We offer our clients a full range of cylinder services, from dismantling and diagnosis, to complete reconditioning services.

We frequently repair the following categories of hydraulic cylinders:

- Telescoping cylinders

- Large bore cylinders

- Multi-stage cylinders

- Mobile crane cylinders

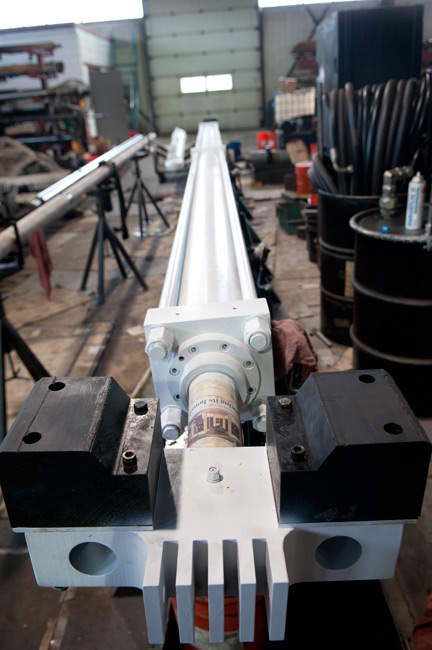

Our facilities can accommodate mobile hydraulic crane cylinders that exceed 100 feet in length. We commonly service the following makes and models:

- GMK™

- Grove™

- Liebherr™

- Tadano™

- Link-Belt™

- Krupp™

- Demag™

- Terex™

- Manitowoc™

- Kobelco™

- Hyster and Taylor

- National™

- Lorain™

- Pettibone™

- P&H™

- Hiab™

- Mi-Jack™

Our highly experienced staff is capable of honing to extremely fine tolerances, giving your equipment longer life and peak performance.

In the case of cylinder shafts, if repairs aren’t possible, we can manufacture hard chrome shafts to your exact specifications.

Adapting a piston or a gland to meet your specific needs can be an effective cost saver, often resulting in a significantly lesser cost than that of replacing an entire cylinder.

- (Bearing surface has been brazed onto a cylinder piston)

- (Bearing surface is being machined down on a cylinder piston)

- (Large hoist cylinder repaired and tested)

- (Lift cylinder repaired and tested)

- (New cylinder barrel being welded on to an existing cylinder blind end)

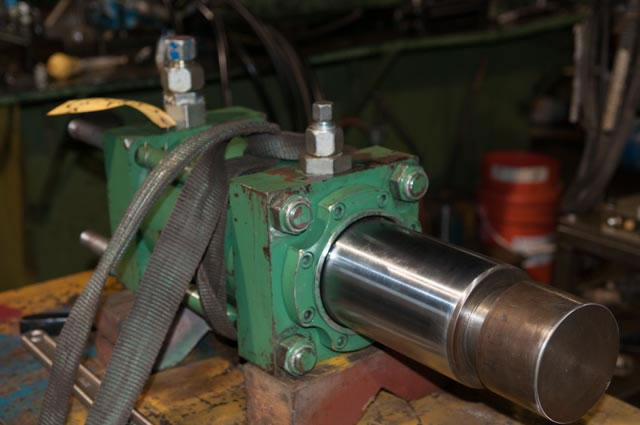

- (disassembly of Liebherr crane cylinder)

- (Cushioned tie rod cylinder before dissassembley and repair)

- (disassembly and diagnostic of cylinder before repair)

- (Liebherr crane cylinder for repair)

- (Large crane cylinder prior to disassemley and repair)

- (Large crane cylinder being delivered to our facility)

- (split cylinder barrel to be replaced)

- (Cylinder for blow moulding application to be rebuilt)

- (Large tie rod cylinder prior to repair)

- (Rebuilt walking floor mechanism under test)

- (Excavator cylinder being disassembled)

- (Piston from blow molding cylinder machined and chromed to specification)

- (Clamp cylinders rebuilt and tested)

- (Grove lift cylinder repaired and tested)

- (23' hydraulic ram from bailer rebuilt, rod chromed, new glands machined etc.)

Finally, we always recommend a full seal replacement on all the cylinders we work on, as new seals are essential to ensure maximum performance. In addition to carrying our own seal stocks, we can source from all leading suppliers and OEMs. We can also custom make seals to suit.