Our Capabilities:

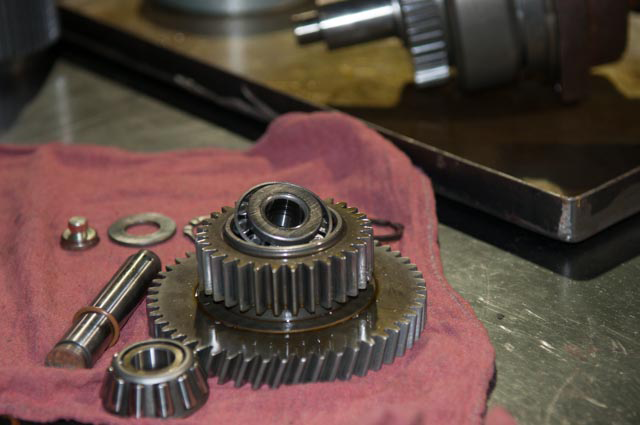

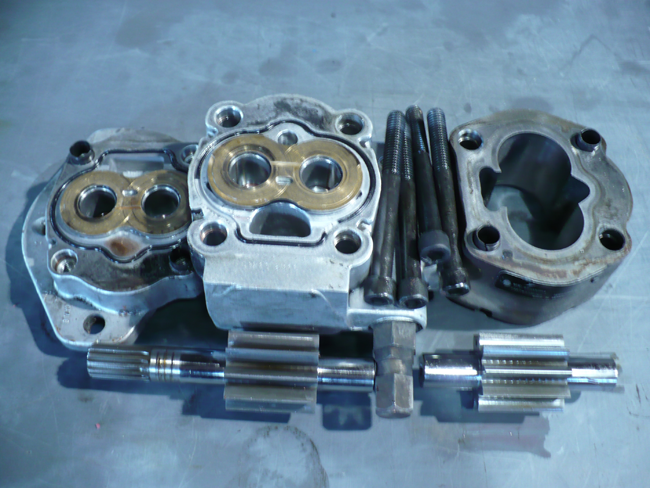

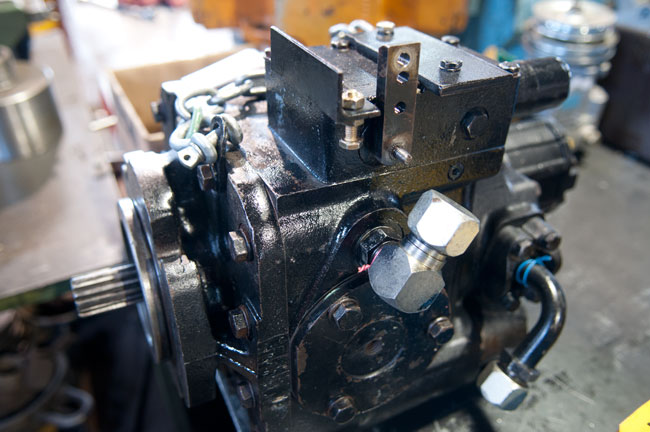

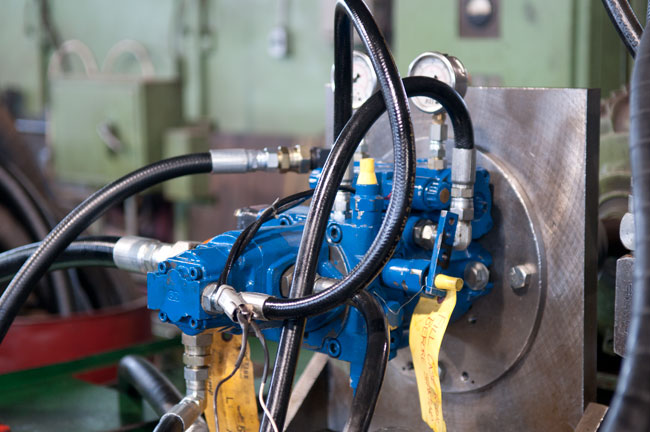

- Pump, Motor, Valve & PTO Refurbishment

- Winch & Gearbox Repair

- Hydraulic Cylinder Repair

- Hydraulic Cylinder Manufacturing

- Mobile Equipment Service

- Remanufacture & Retrofit Existing Equipment

- Hydraulic Power Units & Controls

- Custom Machining & Fabrication

- Industrial Hard Chrome Plating

- Mobile Service

- Preventative Maintenance Contracts

- Service Exchange Program

Hydraulic Pump, Motor & Valve Refurbishment:

In its early days, Action Hydraulics built its reputation on hydraulic component repair, and it still continues to be our expertise. Our salvage rate for damaged hydraulic components exceeds 80%.

In its early days, Action Hydraulics built its reputation on hydraulic component repair, and it still continues to be our expertise. Our salvage rate for damaged hydraulic components exceeds 80%. We commonly repair, rebuild and service:

- Pumps and Motors - Vane, Piston or Gear Type

- Control Valves - Electric, Pilot or Manual Operated

- Hydrostatic Transmissions

Likewise, because we have our own parts inventory, Action Hydraulics is fully capable of repairing cartridge kits.

Initial disassembly, inspection and quotation are carried out free of charge.

Testing services we offer include: Detecting fractures through Magna Flux, and cracking pressure, flow, and leakage tests.

Our component repair services include:

- Chroming and grinding spools

- Honing chambers

- Machining poppet seats

- Manufacturing difficult to source parts such as springs, poppets, and spools

Our rigorous test procedures require that every rebuilt pump is tested for volumetric efficiency, external leakage, and sound levels. Your rebuilt components will undergo cyclic endurance tests before ever being shipped back to you. Our dedication to quality workmanship ensures that before any component is returned to our clients, it either meets or exceeds OEM specifications.

If you require assistance with commissioning services, our trained and experienced staff is also available for on-site hydraulic component commissioning.

- (Corroded manifold salvaged through careful counter boring process)

- (Lapping components from a hydraulic motor)

- (Tear down of a Denison vane pump reveals split shaft)

- (Muncie PTO tear down)

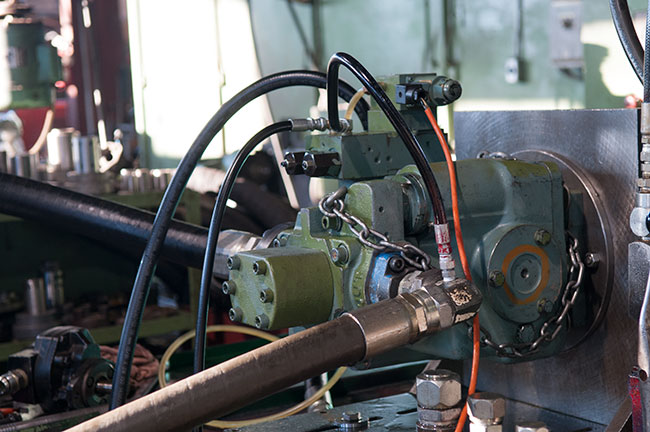

- (PTO to be resealed and rebuilt)

- (Flow testing a hydraulic pump)

- (Piston pump being diagnosed)

- (Simple gear pump tear down)

- (Spool removed for repair)

- (Control valve from Gradall equipment to be repaired and tested)

- (Commercial control valve repaired prior to installation on roll off truck)

- (Sunstrand pump repaired and tested)

- (Rexroth piston pump for closed loop system under test after repair)

- (Daikin piston pump with horsepower control under test after repair)

- (Hydraulic manifold from- bailer refurbished and tested)